Because graphite materials possess a series of unique properties suitable for manufacturing wear-resistant parts, they are currently also widely used to produce bearings for special working conditions. Graphite bearings are widely used in places where grease lubricants are not allowed when the bearings are in operation. For instance, in the bearings of conveyors in industries such as food, beverages, textiles, and chemicals, dryers in the paper industry, fabric dryers in the textile industry, artificial fiber textile machines, cigarette manufacturing equipment, and submersible pump motors, the use of grease lubricants in these places will inevitably cause contamination and thus is prohibited. Graphite bearings have a strong self-lubricating performance and can operate for a long time without the use of lubricating oil.

When choosing graphite bearings, the operating temperature of the bearings should also be taken into consideration. This temperature is composed of two factors: one is the temperature of the medium around the bearing, and the other is the frictional heat generated on the friction surface of the bearing. It is well known that graphite bearings of various materials are allowed to be used at different temperatures. Therefore, it is necessary to select bearings of appropriate materials based on the operating temperature conditions. When the bearing is immersed in liquid or splashed by liquid (wet operation), its friction and wear are greatly reduced. In addition, the liquid can help dissipate the heat generated by friction, which greatly increases the allowable PV value of the graphite bearing. In fact, in this case, the allowable PV value may be 1,000 times higher than that during dry operation.

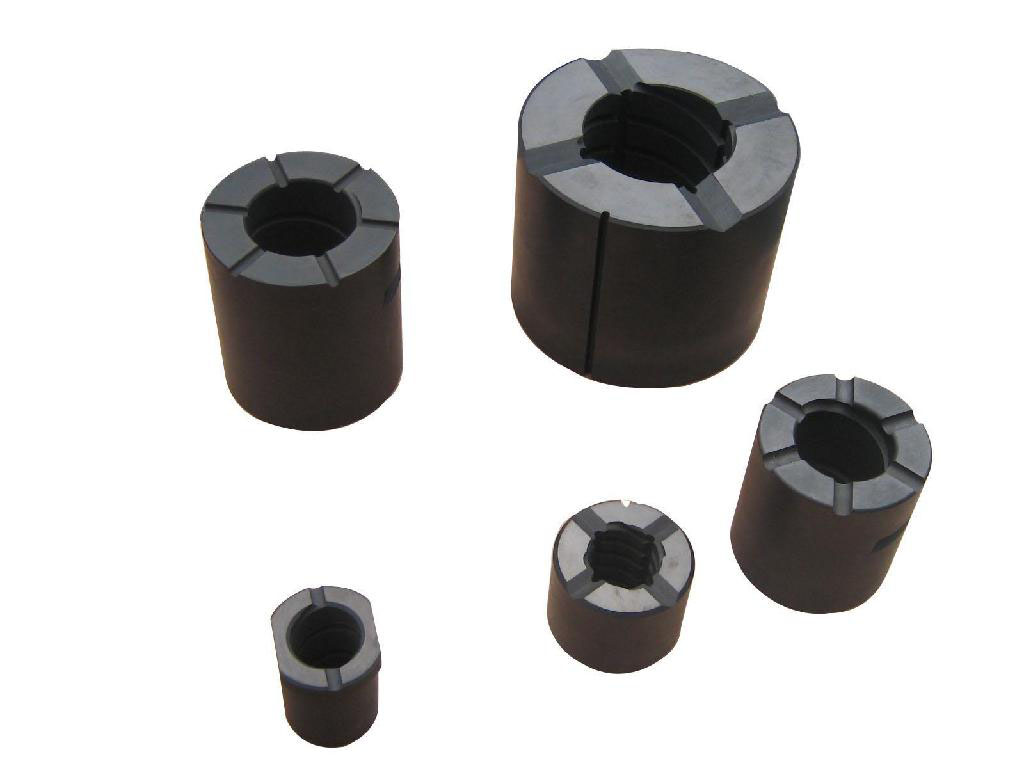

Graphite bearing

Graphite bearings are widely used in places where grease lubricants are not allowed when the bearings are in operation.

Reviews

There are no reviews yet.