Vacuum furnace graphite products are increasingly widely used in vacuum furnaces. They are not only used to manufacture the heating elements and heat insulation screens of vacuum furnaces, but also to produce load-bearing structural parts such as brackets, material trays, guide rails, bolts, bearings, and fan blades. The application of graphite in vacuum furnaces has greatly simplified the design and manufacture of vacuum furnaces, reduced the consumption of metals such as tungsten, molybdenum, tantalum and stainless steel, lowered costs, improved certain performance of vacuum furnaces and expanded their application scope.

Graphite has excellent vacuum performance, thermal conductivity, a small coefficient of thermal expansion, increased strength with rising temperature, good processability, etc. Coupled with its low cost, it is a high-quality and low-cost material.

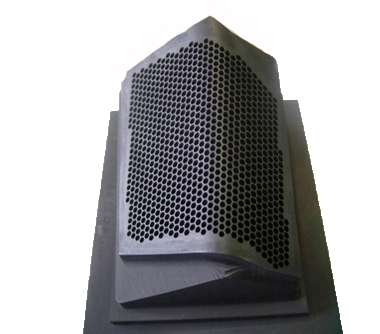

Vacuum furnace graphite products

Vacuum furnace graphite products are increasingly widely used in vacuum furnaces. They are not only used to manufacture the heating elements and heat insulation screens of vacuum furnaces, but also to produce load-bearing structural parts such as brackets, material trays, guide rails, bolts, bearings, and fan blades.

Reviews

There are no reviews yet.